Welcome to Fleury The expert for modular transfer lines

Fleury SA is a swiss company that was founded in 1964. We are developping innovative concept of modular transfer machine. We are also producing components for well-known watchmaking brands using our machines park.

modulo is a modular transfer machine system that includes different types of machining and assembly modules. Our history is based on dry machining for watchmaking. There is also the possibility of machining hard materials such as steel and titaniumand and lead-free brass alloys.

There are currently over 500 modulo units in use.

modulo enables you to manufacture your main plates and bridges in a single operation without stamping, 24 hours a day, 7 days a week.

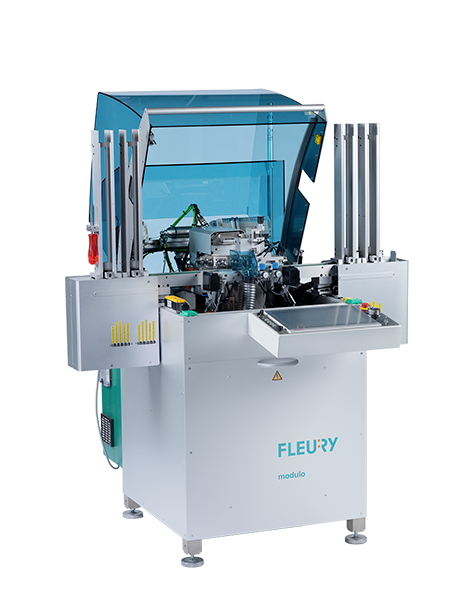

Modulo

The fully automated manufacturing solution with modular linear transfer machines. Your partner for the manufacturing of small components.

Fleury SA has over 50 years’ experience in machine construction for the production of main plates and bridges in the watchmaking industry. There are currently over 500 modulo units in use.

modulo enables you to manufacture main plates and bridges in a single operation without stamping, 24 hours a day, 7 days a week. The production capacity of your production line is always adjustable to your production batch sizes. Designed for batch sizes of 200 to 250,000 components, modulo guarantees a minimal reaction time with minimal production costs.

Processing modules

- modulo ATC 70

- modulo RE

- modulo AL

- modulo HO

- modulo SP

- modulo PE

modulo ATC 70

The new modulo ATC 70 machining center represents the most flexible module of the modulo product lines.

Equipped with a compact chain tool holder with 70 positions, the modulo ATC 70 boasts a level of flexibility never before reached with the modulo system.

Ideal for complex parts and small batches, the modulo ATC 70 permanently keeps all the tools you need for your production lines.

- Maximum spindle speed 35,000 rpm

- Ideal for manufacturing complex parts and for small production batches

- From prototype to mass production with one and the same manufacturing solution

- Equipped with tool breakage laser

DOMAINES D’ACTIVITÉS

modulo RE

FOR VERTICAL MACHINING

The modulo RE is equipped with 10 spindles per unit and guarantees fast, precise and reliable tool changing.

- Highest levels of precision and production output

- Fast and accurate spindle indexing

- Easy maintenance of spindles

- spindle speed 24,000 rpm

- Equipped with tool breakage laser

- Spindles for reaming (optional)

- Indexed spindles for reaming (optional)

- Fixed tool holder for diamond-cutting (optional)

DOMAINES D’ACTIVITÉS

modulo AL

FOR PRECISION HOLE BORING

The modulo AL with its CNC boring head allows to mill holes, pivots and other shapes with just a single tool and only one clamping. You will achieve unrivalled precision.

- Hole diameters from Ø 0.35 mm to Ø 4.5 mm

- Boring unit speed 6’000 rpm

- Pivot diameters max. Ø 2mm

- Dynamic balancing

- Holes, pivots and others shapes finished without precision stamping

- Turning all diameters with a single tool while clamping only once

- Diameter tolerance ±2 μm for min. 72h non-stop

- Localisation tolerance 8 μm for min. 72h non-stop

- Equipped with tool breakage laser

DOMAINES D’ACTIVITÉS

modulo HO

FOR HORIZONTAL MACHINING AND SEPARATION

The modulo HO for horizontal machining is equipped with lathe tool holders and with tool spindles. The rapidly rotating fourth axis (C-axis) allows turning operations and milling, drilling and thread-cutting work in indexed mode. Thanks to a special mechanism, you can separate the finished part from the blank fully automatically.

- Horizontal machining with 4 axis

- 10 tools, fixed or rotating

- Turning, drilling, thread-cutting, milling

- Automatic separation and palletisation

- Equipped with tool breakage laser

DOMAINES D’ACTIVITÉS

modulo SP

FOR JEWEL- AND PIN-SETTING, AS WELL AS PREASSEMBLY

The modulo SP jewel and pin-setting module presses in rubies, pins, eccentric pin, brass tube and other components. A great many assembly steps in your watchmaking operation can be fully automated.

- Assembly of micro-components such as rubies, pins and so on…

- 20 pressing-in tools/tool holder

- 20 component pallets

- Preassembly of mechanisms, wheels, bridges, springs, etc.

- Inspection camera

- Measuring of height, force and component presence

- Pressing-in to stop/height/force/iterative, etc.

- CAM and HMI integrated

DOMAINES D’ACTIVITÉS

modulo PE

FOR DECORATION WITH CIRCULAR GRAINING

The modulo PE circular graining module is equipped with a system for the automatic tool length setting and reshaping of corundum rubber tools. Sufficient tools can be stored in the tool magazine to facilitate a high level of autonomy. Further equipped with a measuring system for a better process reliability.

- Fully automatic circular graining

- Circular graining with perfectly shiny finish

- 2 parts are machined simultaneously

- Automatic height-compensation for wear and tear of corundum rubber tools

- Automatic tool magazine for reloading corundum rubber tools

- Clamping with free workpiece surface